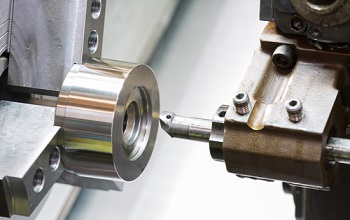

CNC Machining

Chemplast showcases a full scale CNC machine shop for tool repair, dye repair, and machining specialty parts.

CNC machining (Computer Numerical Control machining) is a manufacturing process that uses computer-controlled machines to remove material from a workpiece to create a desired shape or part. It’s widely used for precision manufacturing in industries like aerospace, automotive, medical, and electronics. CNC machining is highly automated and can produce complex, precise parts efficiently.

Here’s how CNC machining works:

- Design: A part is first designed using CAD (Computer-Aided Design) software. The design specifies the shape, dimensions, and features of the part.

- Programming: The CAD design is then converted into a set of machine instructions using CAM (Computer-Aided Manufacturing) software. These instructions, called G-code, dictate the exact movements of the CNC machine, including the speed, direction, and tool changes required.

- Material Setup: A block of raw material (usually metal, plastic, or composite) is secured on the CNC machine’s worktable.

- Machining Process: The CNC machine uses a variety of tools (like drills, mills, lathes, and grinders) to precisely cut away material from the workpiece, following the programmed instructions. The machine can move along multiple axes (usually 3, 4, or even 5) to create the desired shape.

- Finishing: After the initial machining, the part may go through additional steps, such as polishing, deburring, or surface treatment to achieve the final finish.

Types of CNC Machines:

- CNC Milling: Involves rotating a cutting tool and moving it across the workpiece to remove material.

- CNC Turning: The workpiece rotates while a stationary cutting tool removes material. It’s typically used for cylindrical parts.

- CNC Lathes: Used for parts that require a rotational motion, like shafts, wheels, or tubes.

- CNC Routers: Primarily used for cutting large, flat materials like wood, plastic, and foam.

- CNC EDM (Electrical Discharge Machining): Uses electrical sparks to cut through hard materials, often for intricate, hard-to-machine parts.

Advantages of CNC Machining:

- Precision: CNC machines can produce parts with very tight tolerances, often down to micrometers.

- Repeatability: Once a CNC program is created, it can be run repeatedly with consistent results, making it perfect for mass production.

- Complexity: CNC can create very complex parts that would be difficult, if not impossible, to make manually.

- Automation: CNC machines can operate with minimal human intervention once set up, making them more efficient and reducing the risk of human error.

CNC machining is ideal for creating parts with complex geometries and fine details, making it one of the most common methods for producing precision-engineered components.

Please call us at 281-208-2585 or email at sales@chemplastinc.com for all your machining needs.